The Design and Mechanical Technologies section deals with the study of advanced design issues and topics related to innovation and development of new products and manufacturing processes, due to the overall view of the integrated systems of product development and production.

In addition, the researchers engaged in this section adress aspects related to the life cycle of products (such as design, material investigation and choice, production, testing and management in operation), and methodologies (such as computer-aided design and production tools).

The aim of the Design and Mechanical Technologies section is to study and develop innovative and eco-friendly products and manufacturing processes, using innovative design tools that allow to support both the definition phase of the configurable and customizable product, and its manufacturing, also through the implementation of specific design tools, and the Life Cycle Assessment (LCA) methodology for the evaluation of the environmental impact from cradle to grave.

The section carries out research activities in the following areas:

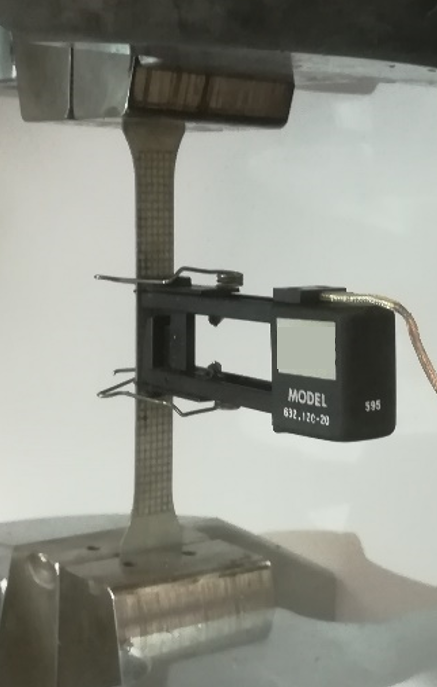

- static, dynamic and cyclical characterization of the mechanical properties of metallic, polymeric and composite materials, both in terms of analytical and experimental aspects

- analysis based on Finite Element Method (FEM) for design and control of production processes

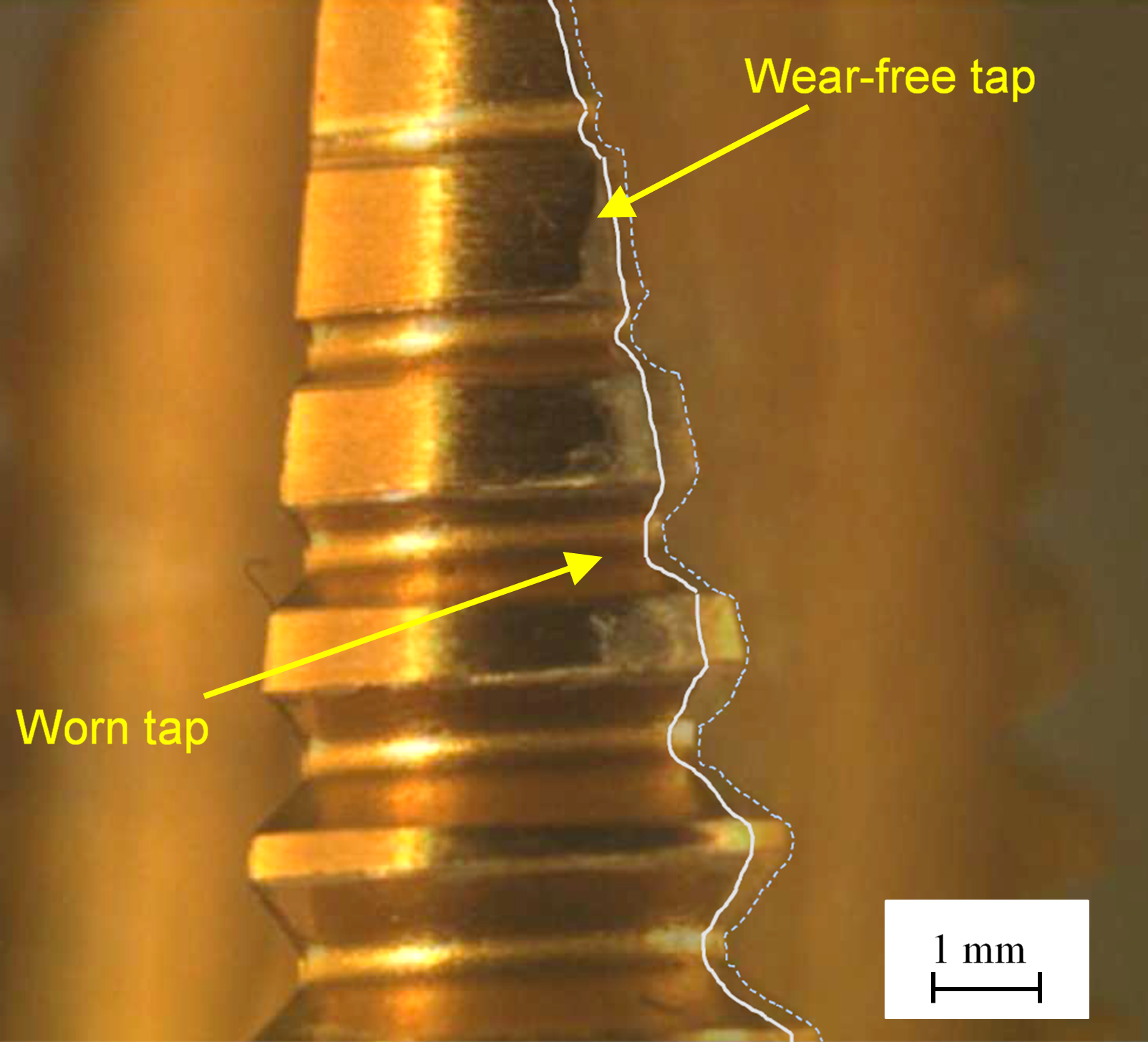

- study of innovative manufacturing processes, both in the area of plastic deformation, machining and welding operations

- development of innovative and eco-sustainable processes for materials re-use and recycling

- analysis based of LCA methodology applied to products and manufacturing processes

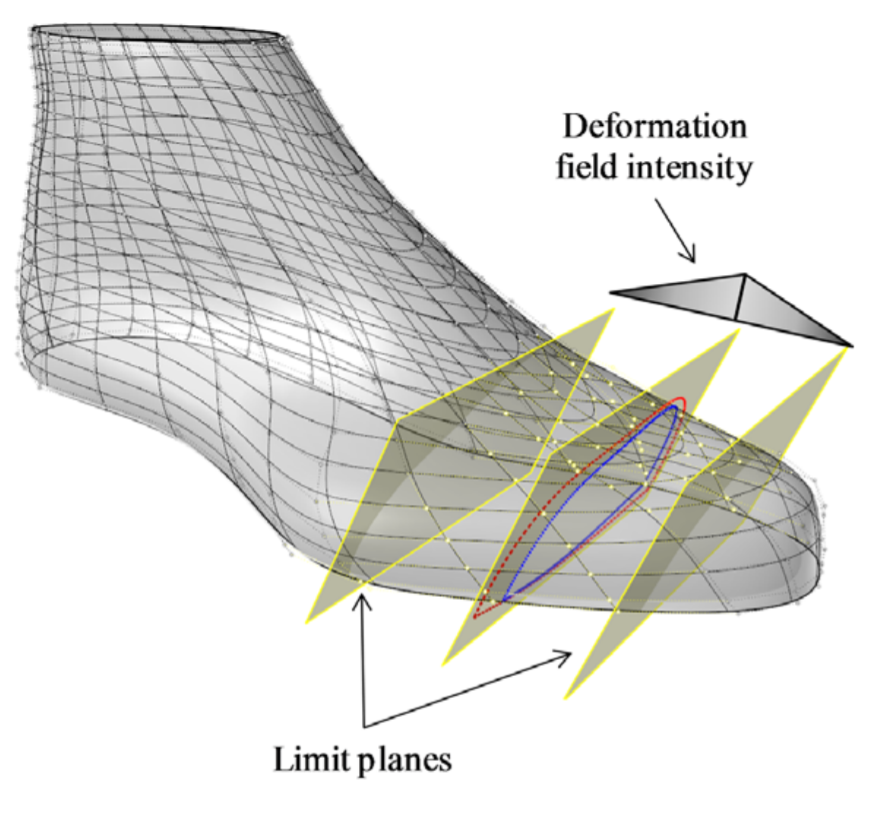

- case studies analysis of Reverse Engineering integrated in a design process

- development of CAD-Based customized methods and systems

- development of methods based on Virtual Prototyping and Model Based Design

- development of methods and tools to support the product re-design phase

The researchers involved in the section also collaborate with companies, competence centers and industrial stakeholders, offering various types of consultancy and support services such as:

- study, definition and implementation of methodologies and tools for:

- Design for Manufacturing and Design to Cost,

- Design for Additive Manufacturing

- multi-objective design optimization

- design of eco-sustainable products and processes

- Reverse Engineering

- virtual prototyping of products;

- development and implementation of constitutive models of metallic, polymeric and composite materials

- numerical simulations of complex manufacturing processes;

- environmental impact assessments of products and manufacturing processes;

- implementation of measurement chains and detection of data aimed at analysing the relationships between the input and output parameters of the process, in order to obtain parts defect-free and characterized by high mechanical properties;

- support for technology transfer and consultancy in research programs.

The following researchers refer to this section:

– Asnaghi Silvano Leonardo

– Cannizzaro Orlando

– Gianluca Chiappini (contact person of the section)

– Cicconi Paolo

– Galtieri Giovanna

– Mandolini Marco

– Rossi Marta

– Roveda Loris

– Simoncini Michela